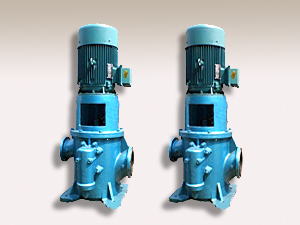

3GL螺杆泵

1、介质为直线连续输送、无搅拌、无脉动。

2、结构简单、拆装方便。

3、体积小,重量轻。

4、振动小,噪音低。

5、压力高、效率高。

主、从螺杆16MnCrS5,40Cr,45,38CrMoALA

泵体:HT200,QT450-10,ZCuSn10Pl,ZG270-500

3GL型螺杆泵系列说明

| |||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||

材料组合代码 | 泵体 | 衬套 | 使用范围 |

W1 | HT200 | 稀土铜钼球铁 | 可低压输送润滑性较差,粘度适当的液体,如燃油等。 |

W2 | HT200 | ZL109 | 可低压输送润滑性好,粘度适当的液体,如润滑油等。 |

W3 | QT450-10 | ZL109 | 用于特殊场合(如船用泵)低压输送润滑性较好,粘度适当的液体,如润滑油等。 |

W4 | QT450-10 | 稀土铜钼球铁 | 用于特殊场合(如船用泵)低压输送润滑性较差,粘度适当的液体,如燃油等。 |

W21 | HT200 | ZCuSn5Pb5Zn5 | 可在较高压力下输送润滑性较差,粘度较低的液体,如重油、燃油等。 |

W23 | QT450-10 | ZCuSn5Pb5Zn5 | 用于特殊场合(如船用泵) 有较高压力下输送润滑性较差,粘度较低的液体,如重油、燃油等。 |

系列代号 | 主要用途 | 性能范围 | |

流量 m3/h | 压力 MPa | ||

3G | 输送3-20oE润滑油, 温度≤80℃,Lub oil visc3-20oE;temp≤80℃ | 0.6-570 | 2.5 |

3GR | 输送3-50oE重质燃油, 温度≤120℃,Heavy feul lil visc3-50oE;temp≤120℃ | 0.6-570 | 2.5 |

3GR | 输送1.2-5oE轻质燃油, 温度≤120℃,Light feul oil visc1.2-5oE;temp≤120℃ | 0.6-570 | 1.6 |

3GW | 输送高温加热燃油, 温度≤150℃,High temp feul heated oil;temp≤150℃ | 0.6-363 | 1.6 |

3GN | 输送100oE高粘度油料, 温度≤80℃,High visc oil 100oE;temp≤80℃ | 0.6-636 | 2.5 |

型号 | 排出压力 | 流量 Q | 转速n | 必需汽蚀余量 rm | 效率η % | 电动机 | ||

m3/h | L/min | 功率kw | 型号 | |||||

25×4-46 | 1.0 | 0.8 | 13 | 1450 | 4 | 62 | 0.75 | Y802-4 |

2.5 | 0.6 | 10 | 60.6 | 1.5 | Y90L-4 | |||

1.0 | 2.0 | 33 | 2900 | 4.5 | 59.4 | 1.5 | Y90S-2 | |

2.5 | 1.6 | 26 | 69 | 3 | Y100L-2 | |||

30×4-46 | 1.0 | 1.6 | 26 | 1450 | 4.5 | 63.5 | 1.1 | Y90S-4 |

2.5 | 1.2 | 20 | 61 | 2.2 | Y100L1-4 | |||

1.0 | 3.6 | 60 | 2900 | 5 | 60 | 2.2 | Y90L-2 | |

2.5 | 3.2 | 53 | 69 | 4 | Y112M-2 | |||

36×4-46 | 1.0 | 2.8 | 46 | 1450 | 4.5 | 66 | 2.2 | Y100L1-4 |

2.5 | 2.4 | 40 | 66.5 | 4 | Y112M-4 | |||

1.0 | 6.5 | 108 | 2900 | 5 | 60.5 | 4 | Y112M-2 | |

2.5 | 6 | 100 | 72 | 7.5 | Y132S2-2 | |||

42×4-46 | 1.0 | 4.8 | 80 | 1450 | 5 | 62 | 4 | Y112M-4 |

2.5 | 4.2 | 70 | 73 | 5.5 | Y132S1-4 | |||

1.0 | 10.5 | 175 | 2900 | 5.5 | 61 | 5.5 | Y132S1-2 | |

2.5 | 10 | 166 | 72 | 15 | Y160M2-2 | |||

45×4-46 | 1.0 | 6.3 | 106 | 1450 | 5 | 70 | 3 | Y100L2-4 |

2.5 | 5.9 | 99 | 74 | 7.5 | Y132M-4 | |||

1.0 | 13.5 | 225 | 2900 | 5.5 | 60 | 7.5 | Y132S2-2 | |

2.5 | 13 | 217 | 75 | 15 | Y160M2-2 | |||

60×4-46 | 1.0 | 15.5 | 255 | 1450 | 5 | 71.3 | 11 | Y160M-4 |

2.5 | 14.5 | 245 | 74 | 15 | Y160L-4 | |||

1.0 | 32 | 533 | 2900 | 5.5 | 63 | 18.5 | Y160L-2 | |

2.5 | 31.5 | 525 | 77 | 37 | Y200L2-2 | |||

70×2-46 | 0.6 | 24 | 400 | 1450 | 5 | 71 | 7.5 | Y132M-4 |

1.0 | 23.5 | 390 | 75 | 11 | Y160M-4 | |||

1.6 | 22.5 | 370 | 76 | 15 | Y160L-4 | |||

70×4-46 | 1.0 | 24.5 | 408 | 1450 | 5 | 72.5 | 18.5 | Y180M-4 |

2.5 | 23.5 | 392 | 79 | 30 | Y200L-4 | |||

80×2-46 | 0.6 | 36.5 | 608 | 1450 | 5 | 72 | 11 | Y160M-4 |

1.0 | 35 | 594 | 75.5 | 18.5 | Y180M-4 | |||

1.6 | 34.5 | 575 | 76.5 | 22 | Y180L-4 | |||

80×4-46 | 1.0 | 37 | 617 | 1450 | 5.5 | 72 | 30 | Y200L-4 |

2.5 | 35 | 590 | 78.1 | 45 | Y225M-4 | |||

100×2-46 | 0.6 | 72.5 | 1208 | 1450 | 5 | 73 | 22 | Y180L-4 |

1.0 | 71 | 1183 | 77 | 37 | Y225S-4 | |||

1.6 | 60.5 | 1158 | 79 | 45 | Y225M-4 | |||

100×4-46 | 1.0 | 72.5 | 1208 | 1450 | 5.5 | 73 | 55 | Y250M-4 |

2.5 | 70 | 1165 | 78.5 | 75 | Y280S-4 | |||

S100×3-27 | 0.6 | 72 | 1196 | 1450 | 6 | 62 | 22 | Y180L-4 |

1.6 | 70 | 1160 | 72 | 55 | Y250M-4 | |||

2.5 | 69 | 1145 | 74 | 75 | Y280S-4 | |||

S120×3-27 | 0.8 | 123 | 2055 | 1450 | 6 | 74.5 | 55 | Y250M-4 |

1.5 | 120 | 2010 | 76 | 90 | Y280M-4 | |||

2.5 | 115 | 1920 | 78.5 | 132 | Y315M-4 | |||